製造工程

製造工程

1.こね前工程(こねまえ)

小麦粉に食塩水を入れ、こね合せて手延べ麺の生地を作ります。

2.足踏み工程(あしぶみ)

生地をロールで回転させながら、生地の中の空気を抜いて、水分を均一にしていきます。

3.板切工程(いたぎ)

生地を切り出して桶に巻いていきます。

4.油返し工程(あぶらがえし)

製麺工程で麺同士がくっ付かないよう、そして麺帯が乾燥しないように、

麺帯の表面に食用油を塗っていきます。

5.細目作業(ほそめ)

熟成の後、縒りを掛けながら細くし、麺紐(めんひも)にしていきます。

6.小均工程(こなし)

熟成の後、さらに細くしながら、麺同士がくっ付かないように、

縒りを掛けながら麺紐の表面に澱粉を振っていきます。

7.掛け巻き工程(かけまき)

熟成の後、麺紐に縒りを掛けながら、

2本の管に8の字を描くように掛けていき、室箱に入れます。

8.小引き工程(こびき)

熟成の後、麺職人が試し引きを行い、小引き機で均等に延ばしていきます。

9.小分け工程(こわけ)

熟成の後、麺紐を延ばしながら麺同士を箸で分けていきます。

10.門干工程(かどぼし)

延ばした麺紐を門干機につけていきます。

麺紐の状態をみながら、さらに麺紐を延ばします。

11.小割工程(こわり)

一昼夜乾燥の後、麺を切断します。これで麺の長さが決まります。

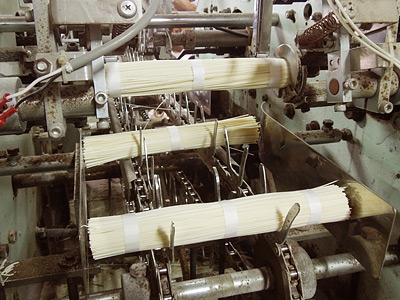

12.計量・結束工程

切断した麺を任意の重さに計り、結束した麺束が金属探知機を通過していきます。

13.製品検査工程

検査担当者が、目視による品質検査を行います。

14.包装・箱詰め工程

麺を包装・箱詰めして出来上がります。